Milk and Food Testing & Monitoring

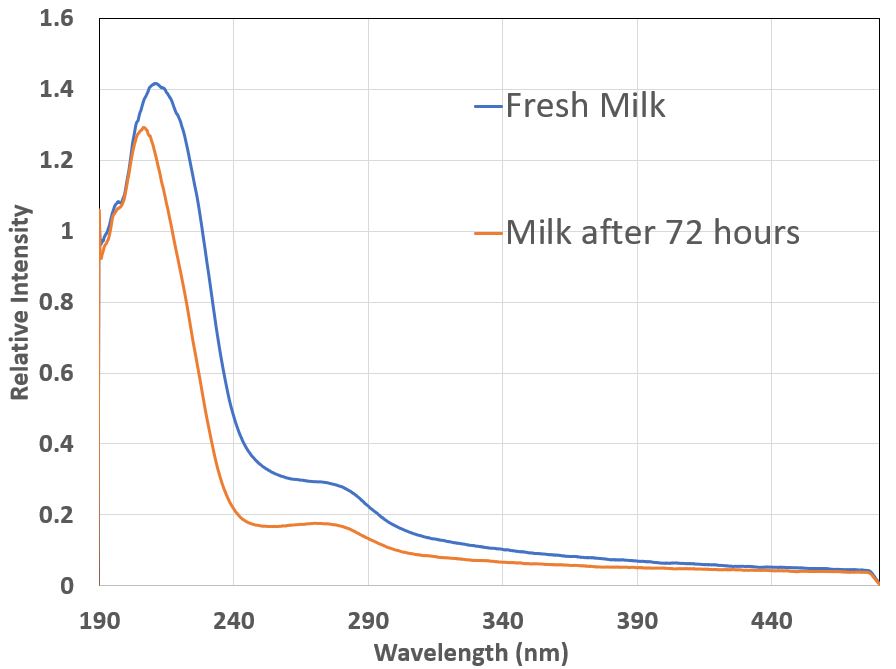

The IDS instrument can be used for quickly measuring the amount and trace concentrations of various molecules present in beverages such as milk and many types of food since such molecules will absorb light in direct proportion to the concentration present. For example, milk will spoil when bacteria producing lactic acid converts the lactose into glucose and galactose. The amount of lactic acid can be detected and measured using the advanced spectroscopy tool and algorithm which can also monitor changes to the beverage over time and at various temperatures and storage conditions. Changes to the food quality can also be quickly monitored during the manufacturing process in order to prevent potential contamination and avoid significant losses to production batches.

Example of an IDS Analysis & Comparison of Milk Quality

In addition to measuring lactic acid in milk, the IDS tool ca be customized to measure the presence of other molecules and food additives present. This can help monitor food quality by analyzing the presence of intentional or non-intentional additives, including potential contamination. The tool can further be used to quickly analyze the color of the food or beverage in order to quickly detect changes that may be caused by temperature, light, or handling and storage conditions.

Various color additives are also widely used in non milk food and beverages. Therefore, determining the concentration of food additives in both liquids or in solid food can be crucial, particularly for consumers with specific food or color dye allergies. Food dyes are broadly used in the manufacturing of consumer products for a variety of reasons. Sometimes they are used to add flavor but often to compensate for the natural color loss. Color fading occurs in fruits, vegetables, and meats during storage or following exposure to light and oxygen. Color additives are also introduced into colorless food products, such as cake frostings, juices, and pie toppings.