Remote Phosphors and RadiantFlexTM

PhosphorTech has been developing optical materials and remote phosphor technologies and products since its inception in 1998 and has one of the earliest known intellectual property in this area involving an LED and a remote phosphor compound.

The RadiantFlexTM technology is a direct result of over a decade of research in various remote phosphor application methods, phosphors, and substrate materials. This is evident in the superior performance of this technology compared to any existing commercial product, not just in terms of luminous efficacy, but also a variety of other performance and cost factors.

Purchase RadiantFlex TM phosphor sheets

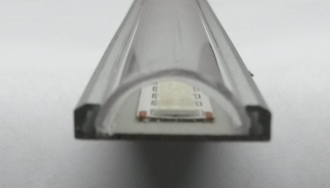

One of the most unique advantages of the RadiantFlexTM phosphor film is the ability to be used in virtually any phosphor-converted LED device ranging from die-level attachment all the way to remote phosphor applications, as shown below.

Award for Significant Achievement in Solid State Lighting R&D

The Remote Phosphor configuration offers significant advantages:

- Uniform light-emitting surface over a large area

- Better color stability in terms of color temperature and rendering index

- Color output customization using a single type of LED light engine

- More consistent flux levels with less angular dependence

- Improved system efficiency and lower operating temperature

- Longer LED and lamp lifespans

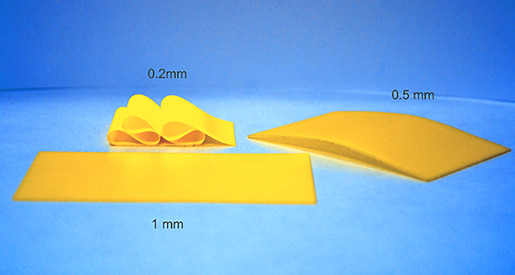

Phosphor sheet can be produced in various thicknesses

Since the phosphor sheet can be produced in thicknesses ranging from as little as 50 microns to several millimeters, the technology is suitable for any LED manufacturing method and can even be processed using the same pick-and-place equipment currently used for die-attachment. This results in significant cost savings for LED manufacturers since it completely decouples phosphor qualification and testing from the LED packaging process.

Thus it eliminates the need for

- Phosphor handling/mixing/optimization capabilities, and

- Phosphor dispensing equipment.

from 0.2mm to 1mm

Cost reduction and flexibility

LED and lamp manufacturers can use a pre-mixed and pre-optimized high performance phosphor product for direct application to commercial LEDs at costs significantly below the costs involved in purchasing, handling, and processing phosphor powders. More importantly, such an approach enables a higher degree of flexibility and color customization using commercially available LEDs, particularly for low volume and specialty applications.

Examples of LED lamps using phosphor films