A customized infrared LED or OLED can be made for a wide range of applications, including IR communications and machine vision technologies such as multispectral (MSI) or hyperspectral imaging (HSI) cameras. Commercial infrared LEDs are limited in terms of output intensity and spectral coverage or bandwidth. A phosphor-based approach using commercial blue (or red) LEDs or lasers can be used to fabricate broadband or narrow-band infrared LED(s) for the near-infrared, short-wave infrared (SWIR), and even mid-wave (MWIR) and long-wave (LWIR) infrared.

In addition, using a remote phosphor approach, it is possible to generate and project infrared light and images over long distances. With just a laser, IR light can be generated at a remote destination without the presence of a power source since the phosphor can be activated optically by transmitted laser light.

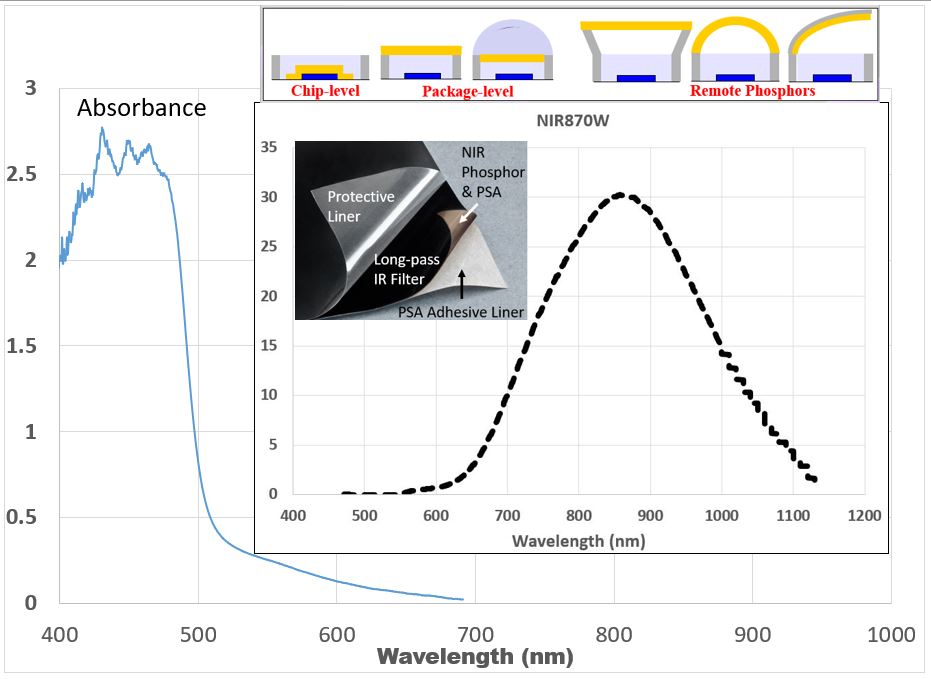

The use of NIR phosphors make it possible to extend the range, sensitivity, and performance of low-cost multi-spectral cameras without the need for expensive and bulky SWIR sensors and equipment. It also makes it possible to customize the object or area lighting to the sensitivity of the camera sensors. With custom infrared phosphor-converted LEDs (pcLED), an MSI or HSI camera can produce multiple single- or narrow-band images over any infrared range between the 700nm-1700nm spectral range. A pcLED can also be made to simultaneously deliver high color rendition visible light, in addition to the infrared. If visible light is not desirable, an IR phosphor film can be manufactured directly on a long-pass filter to remove any remaining VIS light from the LED, as illustrated below. The broadband NIR870W phosphor spectrum shown below is just one out of many IR phosphor options that we can offer for virtually any application or spectral range.

IR phosphor films can be used to fabricate customized IR LEDs for a wide range of LED packages and applications

Phosphor-converted IR LED Source