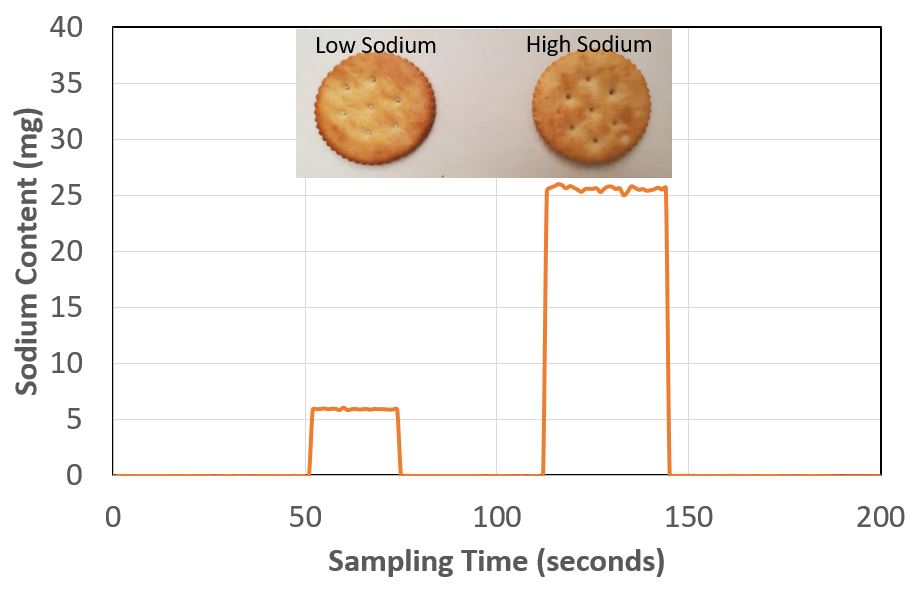

Fast and accurate ingredient analysis of baked food during the production process is crucial for quality control and manufacturing process improvement. The IDS tool can provide instant ingredient analysis of various components and food additives used during the production cycle in order to help minimize production time and maximize process efficiency. The tool is compact, portable, and requires very low maintenance and minimal training. This instrument transforms the traditionally expensive and slow single-channel UV/Vis/IR spectroscopy into a low-cost, modular and multi-channel sensor with rapid and automated sample processing capability. It incorporates a patented technology capable of parts-per-million detection precision that can be used to optically measure the properties of both liquid and solid materials. Since it uses optical-based sensors, it can also deliver high speed and remote non-destructive measurement with minor modification. The system design is both simple and modular and can be quickly calibrated for a wide range of in-line or bench top test applications. The commercial version of the system has been extensively used for ingredient analysis of various liquid suspensions. It has also been used as a high-speed fiber optic sensor for the detection and measurement of water and bulk salt concentrations in cookies and crackers. The graph below shows salt ingredient analysis results when comparing store-bought crackers with low and high sodium content. The system includes hardware, USB drivers, and software, in addition to a user-customizable graphical user interface.

Optical-based Salt Measurement in Crackers

In addition to ingredient analysis, spectroscopy can also be used as a tool for evaluating food color under artificial or natural light environments. Food color can affect the consumer perception of quality. UV/Vis and infrared analysis of food products can also yield a wide range of information regarding the composition of food and any changes in property, quality, or shelf-life as a result of long-term storage, transportation, temperature, and handling.