Blue-free light technology have gained traction recently following numerous studies that established the impact of light on the circadian rhythms. The photo receptors in our eyes are highly sensitive to blue at night (scotopic eye response) and green during the day (photopic eye response). Blue light, therefore, appears to have the strongest impact on the circadian rhythm while red light has minimal impact.

To order the blue-free or zero blue cap (ZB-CAP) for warm white LEDs, please click here.

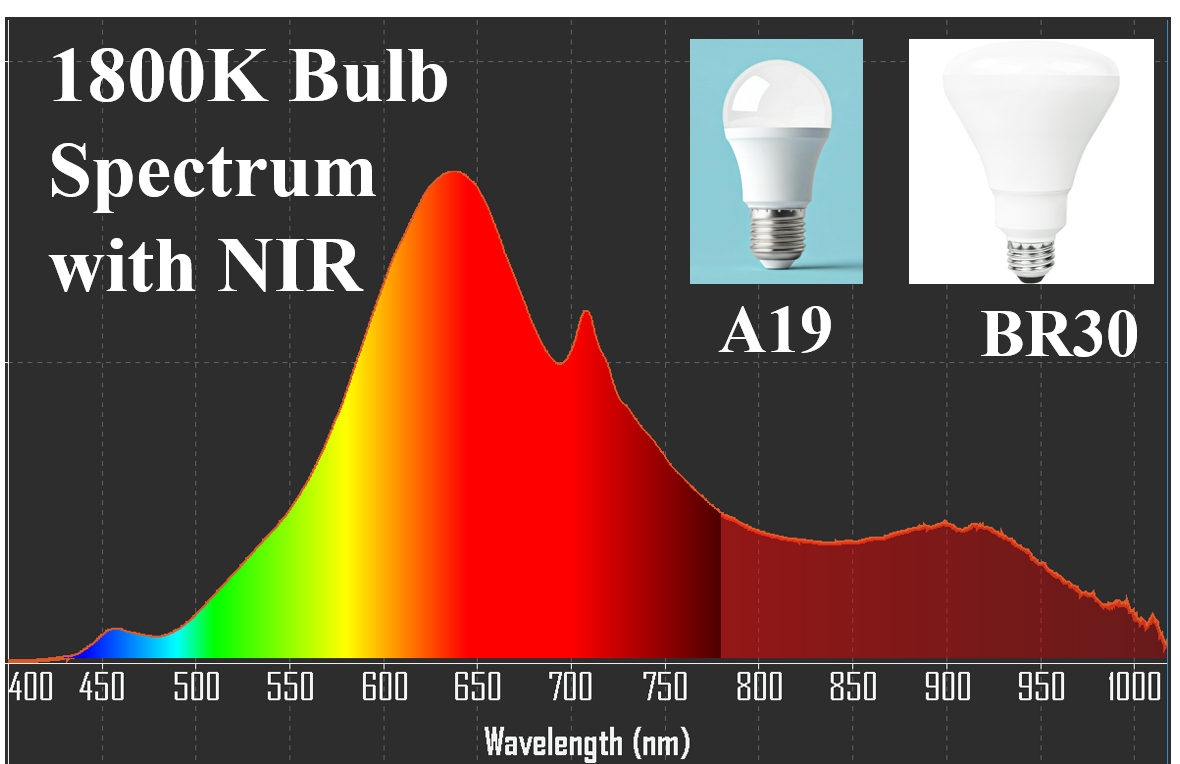

Since white daylight contains significant amount of blue light, exposure to white light during the daytime can have positive effects including boosting alertness and mood. On the other hand, exposure to blue light in the evening can cause sleep disruptions and prevent nighttime rest. That’s where our blue-free light technology can help. When combined with our near-infrared enhanced LED technology, it is also possible to create artificial lighting that closely resemble the sunlight spectrum at various times of the day.

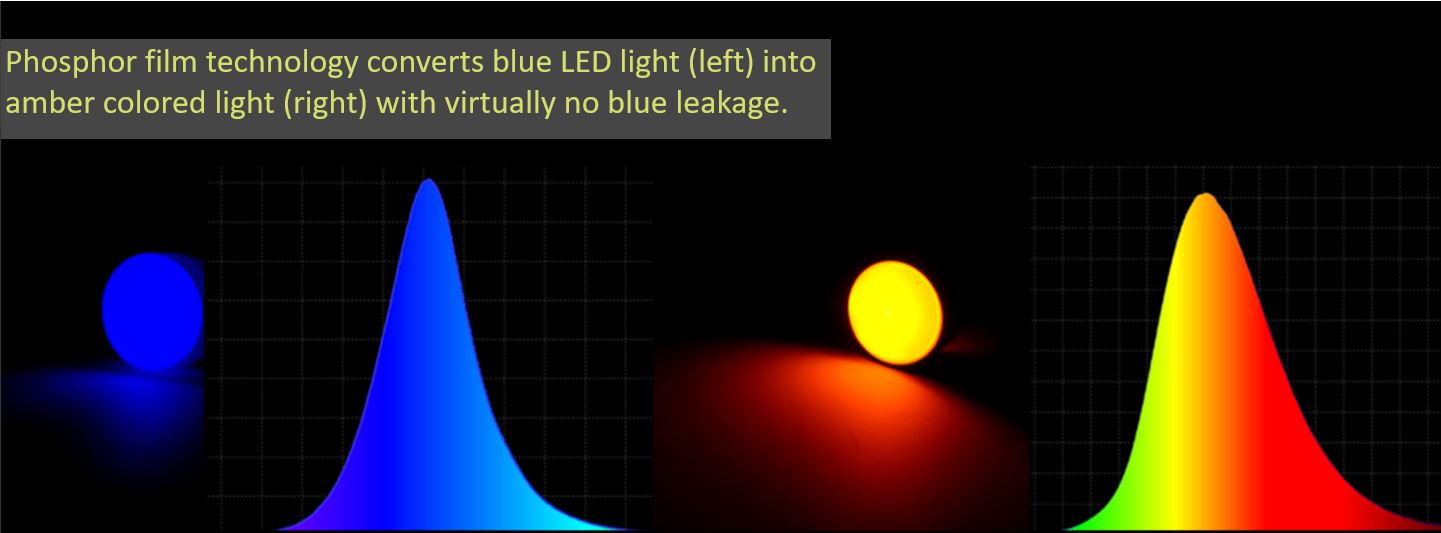

Our unique and proprietary amber phosphor sheet technology can help produce LED light with zero-blue content. The remote phosphor products can be used with blue LEDs or any commercial white LED products that contain a significant amount of blue light. The blue-free light products also enable direct conversion into the SAE Amber Zone for a wide range of automotive, maritime, and aerospace applications.

Phosphor Color Conversion from Blue to SAE Amber

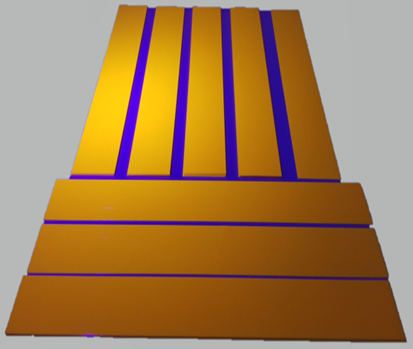

The light-converting films use a unique roll-based coating process to achieve superior performance while simultaneously reducing phosphor material usage between 33-50%, depending on the desired color temperature. The higher performance is a result of increased blue LED light absorption combined with reduced optical scattering losses. The phosphor films are compatible with a wide range of printing technologies including 3D printing, which enable the production of hybrid light-emitting 3-dimensional photonic structures never before possible.

Production of the blue-free amber light sheet products started in 2013 and the company’s ISO 9001 certification was maintained continuously since 2015. Light converting films are used today by several industry-leading LED and lamp manufacturers in the production of a wide range of LED parts annually.

Zero Blue LED Phosphor Plate Products

We also produce low-blue phosphor films and LED bulbs with high near-infrared content and color rendition (CRI) over 90, as shown below. The bulbs exhibit candlelight color temperature around 1800K with at least 50% NIR photon flux. You can purchase the bulbs (2K Type) here or scan the QR codes below.

Low-blue Candlelight LED at 1800K with Infrared and high color rendition (CRI>90)