Transform any Standard Warm White LED Bulb into a Zero Blue Candle Light

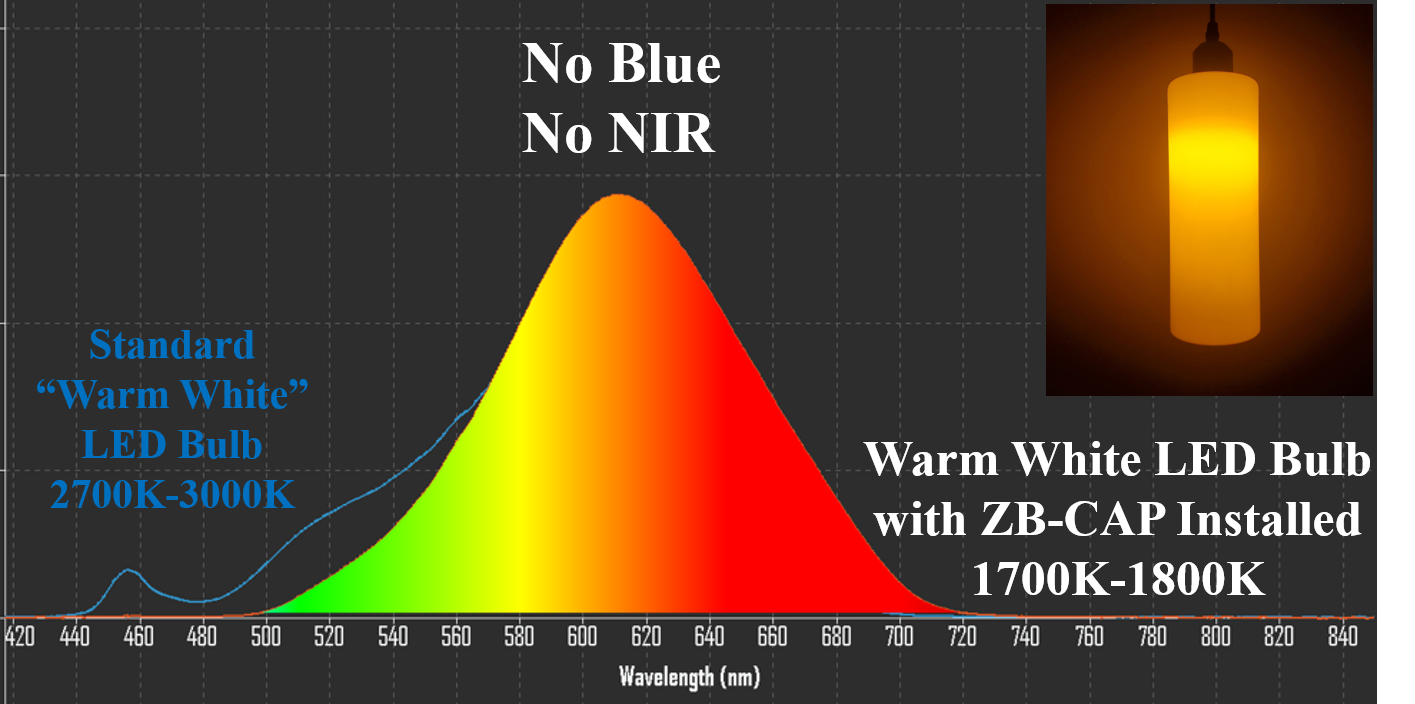

The zero blue LED cap (ZB-CAP) is made possible using proprietary optical structures and advanced materials developed specifically to work with standard LEDs. Unlike other alternatives to improve the quality of artificial light, this invention does not require you to get rid of existing LED bulbs. This translates into significant cost savings for consumers while reducing environmental waste. There are currently billions of LED bulbs installed around the world and it is estimated that 90% of all artificial lighting will be LEDs by the year 2030. Our unique ZB-CAP technology can transform any warm white (~3000K) LED bulb into a zero blue spectrum for general lighting or any other type of illumination. The high performance silicone-based photonic structure can help provide a candle-like no blue spectrum with plenty of light across the visible and with no infrared. This can be achieved at a fraction of the cost compared to alternative zero blue light bulbs and fixtures.

The zero blue LED cap (ZB-CAP) is made possible using proprietary optical structures and advanced materials developed specifically to work with standard LEDs. Unlike other alternatives to improve the quality of artificial light, this invention does not require you to get rid of existing LED bulbs. This translates into significant cost savings for consumers while reducing environmental waste. There are currently billions of LED bulbs installed around the world and it is estimated that 90% of all artificial lighting will be LEDs by the year 2030. Our unique ZB-CAP technology can transform any warm white (~3000K) LED bulb into a zero blue spectrum for general lighting or any other type of illumination. The high performance silicone-based photonic structure can help provide a candle-like no blue spectrum with plenty of light across the visible and with no infrared. This can be achieved at a fraction of the cost compared to alternative zero blue light bulbs and fixtures.

The ZB-CAP technology will also work with most smart LED products, including tunable RGB+CCT light bulbs, when set to warm white color mode. Even when using a higher CCT setting, the ZB-CAP will significantly reduce the level of blue light and contribute to better nighttime sleep and healthier living, regardless of your light color preferences.

The ZB-CAP is guaranteed to provide zero blue light (from warm white) for the entire life of your bulb or we will replace it for FREE.

To see list of ZB-CAP choices available for ordering, please click here.

We are currently taking orders for the 2-inch ZB-CAP film products that will fit A19 and A20 (also A21 and BR30) size LED bulbs with a flat rate first class shipping. If you would like to order NIR-enhanced therapy bulbs, please click here. If you are looking to retrofit other types of LED bulbs or fixtures, please send an email to info@phosphortech.com with your requirements and contact details.

Please also visit our shopping cart page for a full list of NIR-related products.

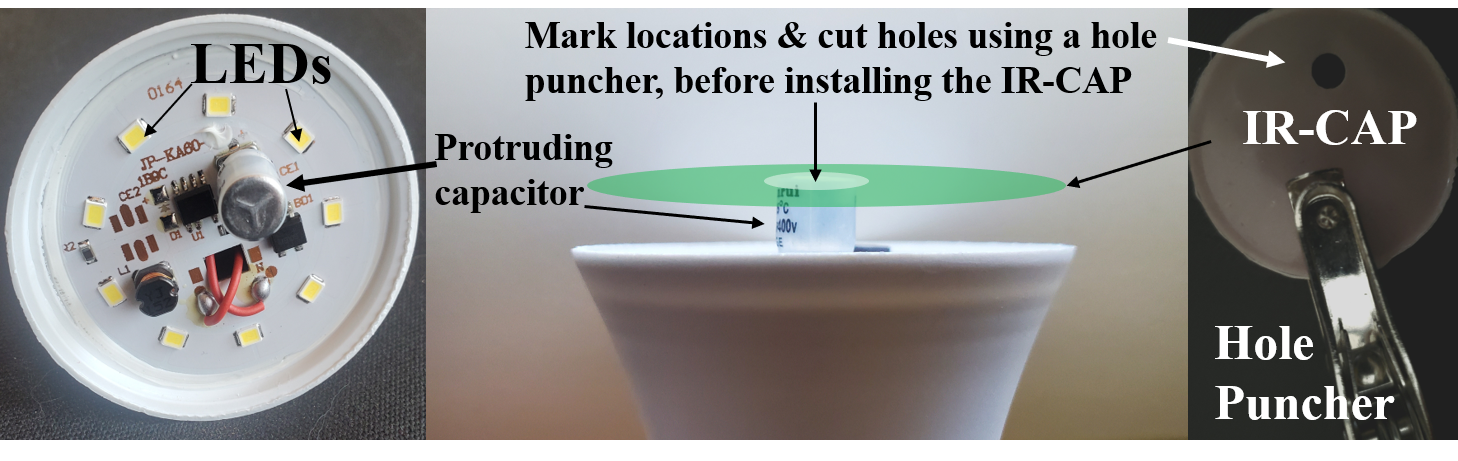

The process for installing the ZB-CAP is exactly the same as that for the IR-CAP shown below.

For bulk orders or to receive a quote, send an email to orders@phosphortech.com with your contact info and quantity requirements…

BEFORE YOU ORDER, PLEASE CHECK YOUR CURRENT LED BULB(S) AND MAKE SURE YOU CAN EASILY REMOVE THE PLASTIC CAP. Some bulb manufacturers use strong adhesives to attach the light diffuser cap. You should try twisting and turning the cap in place few times in order to loosen the adhesive before removing it. Once you are able to loosen the cap, apply pressure to one side with your thumb then pry it open, as illustrated in the previous video. Repeat this process on the other bulbs you have.

Some bulbs may also have large electronic components (like a vertical capacitor) somewhere on the printed circuit board (PCB) alongside the light-emitting diodes (LEDs). The LEDs are generally (but not always) positioned around the perimeter of the PCB. To make the ZB-CAP work effectively with such bulbs, you will need to cut small holes into the silicone film in order to make it fit better. This is very simple and can be done using any regular hole puncher. The holes can be smaller than the component. Just like our IR-CAP, the ZB-CAP is made using silicone, so it can be safely stretched making the holes temporary larger during installation. The goal is to cover ALL LEDs while keeping the ZB-CAP as flat as possible on the PCB. The ZB-CAP needs to extend to the internal edges of the light bulb since the LED diffuser cap is used to hold it down into a fixed position. Covering the small (and slightly protruding) electronic components on the PCB is OK, as long as the LEDs are covered and the ZB-CAP can reach the edge. Finally, snap the plastic diffuser back into place and make sure the silicone sheet is firmly into position by shaking the bulb. If the ZB-CAP is loose, you may need to adjust it by repeating the process.

If you have this type of bulbs, no modification to the ZB-CAP is needed.

Some LED bulbs may have protruding parts. Just like the IR-CAP process shown above, you may need to punch small holes into the ZB-CAP, as shown.

It is also possible to retrofit a BR30 recessed light bulb, but pry tools and a thermal adhesive are required. The adhesive is also needed to fix the 2in ZB-CAP inside the larger size A21 bulbs. Make sure the LEDs are not covered with the adhesive.