Measurement and identification of paints and polymer composites

UV/Vis spectroscopy is a very powerful tool in the analysis of paints and can be used to study the optical/color properties and to identify the concentration of nanofillers and various polymer composites. Using UV/Vis analysis from IDS, the optical properties of paints, pigments, and polymers can be fine-tuned to the desired application and the data can be used to develop new functional materials with unique properties.[vi]

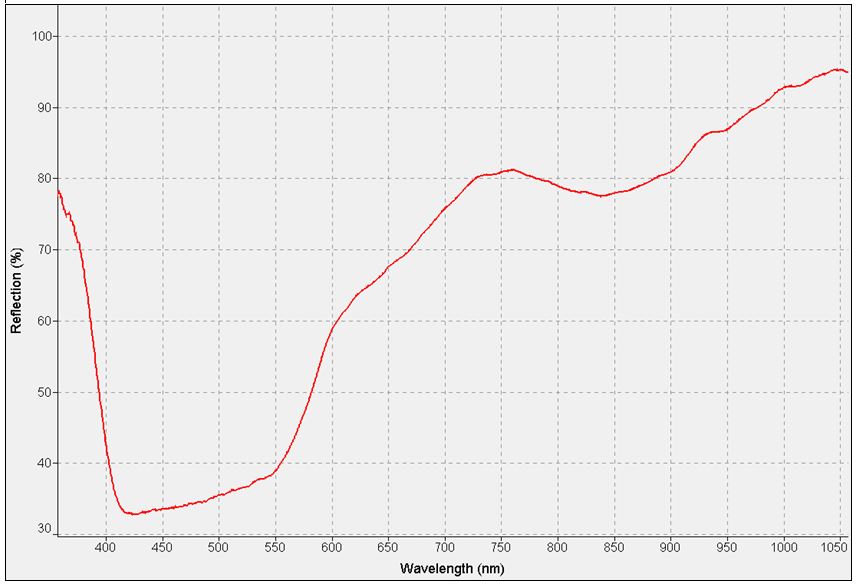

The reflectance spectrum shown below for a red paint sample represents a unique signature that can help identify the material. In addition to using the IDS tool for color matching and design, it can further be used to identify counterfeit products from the originals. By conducting paint analysis and overlapping the spectra from different liquid (or solid) samples, it is possible to identify genuine products from copycats. It is also possible to use this tool along with customized phosphors in order to design low-cost solutions for security tagging and anti-counterfeit enforcement for a wide range of products.

The inorganic and particulate nature of phosphors means that they can be embedded into any product (including paints) during the manufacturing process. Some phosphors can be produced in sub-micron or nano size in order to maintain an effective colloidal suspension. Security phosphors can withstand temperatures over 1000 degrees centigrade. Therefore, a phosphor can survive a fire even when the traditional polymer-based paint and painted product(s) are destroyed. Through material analysis of the residue, the presence of a security phosphor can still be detected. Unlike traditional paints, phosphors can be designed to be chemically inert and still have functional properties in extreme conditions with superior resistance to chemicals, solvents, and acids.

Reflectance Analysis of Red Polymer Paint

The technique has also been successfully used in understanding analyte interactions with molecularly imprinted (MIP) sensors in order to design low-cost MIP sensors with good sensitivity.[vii]

[vi] Sridevi Venkatachalam, “Ultraviolet and visible spectroscopy studies of nanofillers and their polymer nanocomposites”, Spectroscopy of Polymer Nanocomposites, 2016

[vii] Adnan Mujahid, Franz L. Dickert, “Molecularly Imprinted Polymers for Sensors”, Molecularly Imprinted Sensors, 2012