LED phosphors can help produce custom solutions for horticultural and hydroponic LED grow lights used in commercial greenhouses. Phosphor technology can be combined with LED devices in order to optimize plant growth through spectral customization and color tuning. The peaks of photosynthetic efficiency generally fall in the red and blue regions of the Photosynthetic Active Radiation (PAR) range. Although red light energy is generally considered more efficient at driving photosynthesis during the flowering stage for biomass growth, each plant type is different and the science regarding the optimal growth spectrum is constantly evolving.

With remote phosphor technology, it is possible to create and customize using phosphor films your own multi-channel horticultural grow lights or fixtures and use them to experiment with an unlimited number of wavelengths across the ultraviolet (UV), visible and even infrared (IR) parts of the spectrum. This approach will save significantly on light fixture development, implementation, and manufacturing cost since it does not require expensive high power multi-channel LED controllers driving a large selection of red, green, yellow, blue, and white (RGYBW) LEDs. All PAR colors can be generated using phosphors combined with blue or UV/violet LEDs. We can produce simple-to-use and efficient phosphor films for blue, violet, and ultraviolet LEDs using any existing phosphor material.

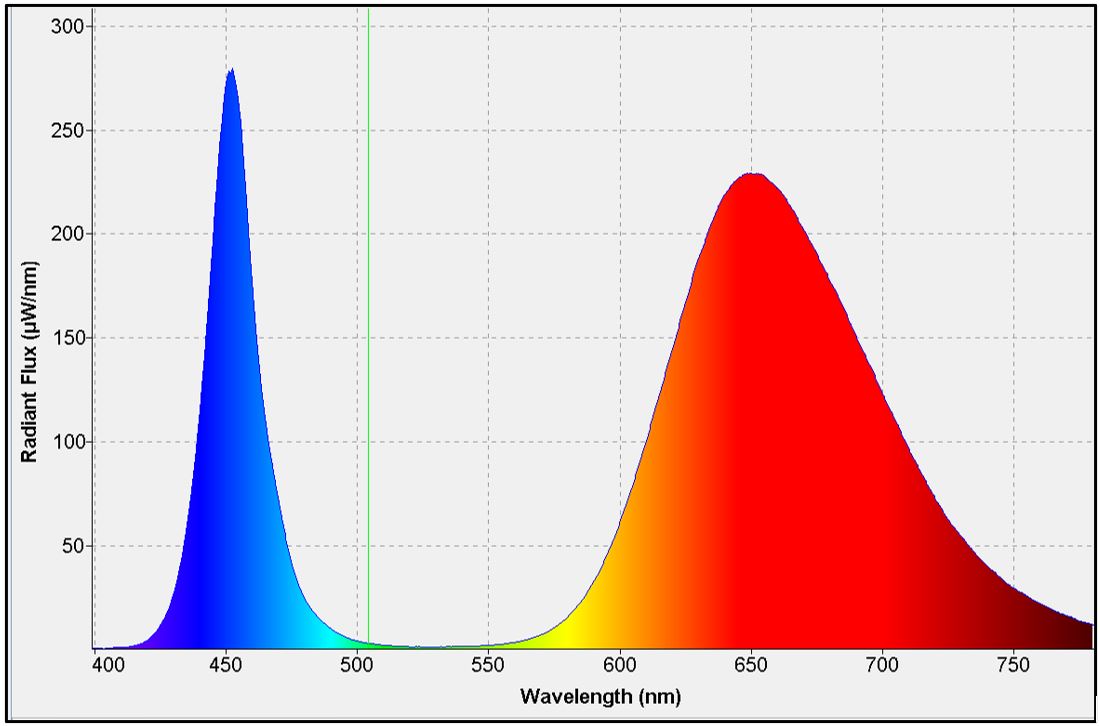

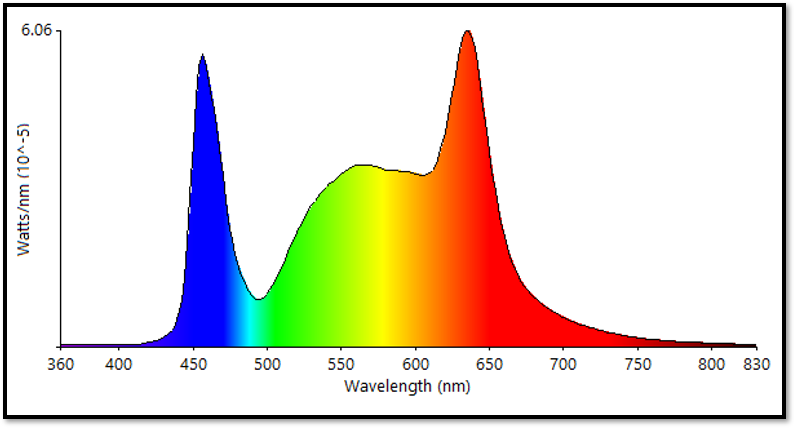

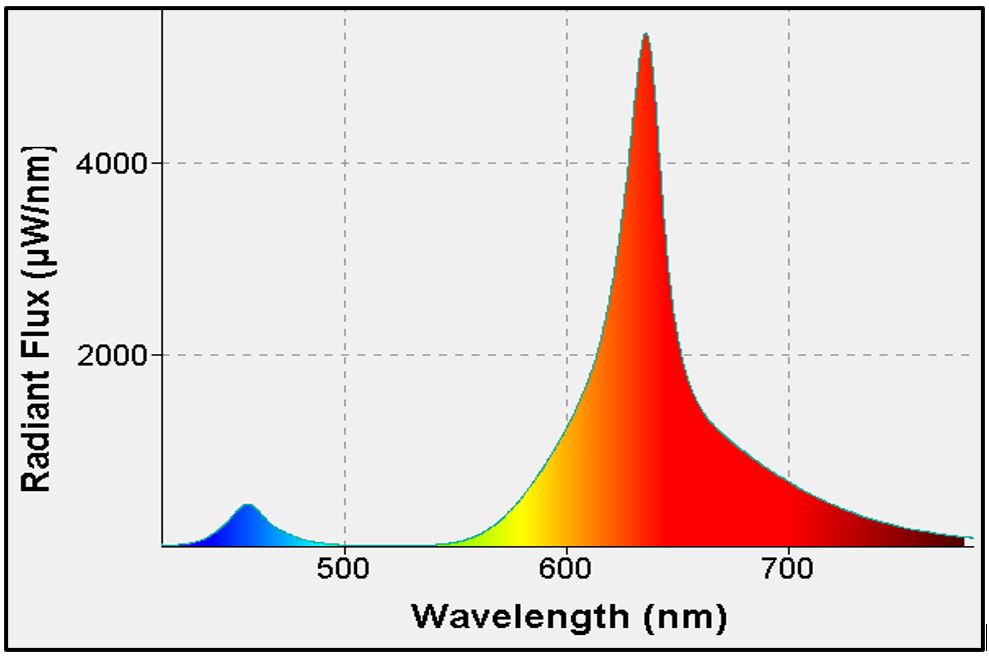

Below are some custom spectra that were designed and implemented for horticultural and hydroponic lighting applications using phosphor-converted LEDs (pcLEDs). The phosphor material can be placed at a remote location or it can be deposited/dispensed directly on the die inside the LED package. Another common approach would be to attach a thin phosphor film on top of the chip-on-board (COB) or surface-mount device (SMD).

Blue & Red LEDs combined with an orange/red phosphor