Data from Fly Ash Testing Using Commercial AEA Systems*

*While this data focuses exclusively on testing fly ash adsorption with commercial AEAs, any material present in colloidal suspensions, powder or aggregate form can be tested. The system is also not limited to commercial air-entertainment agents (AEAs). A wide range of adsorbate molecules can be used such as the methylene blue (MB), which is also included in the database.

Correlation between ASTM Foam Index Method and IDS Method

Correlation between ASTM Foam Index Method and IDS Method

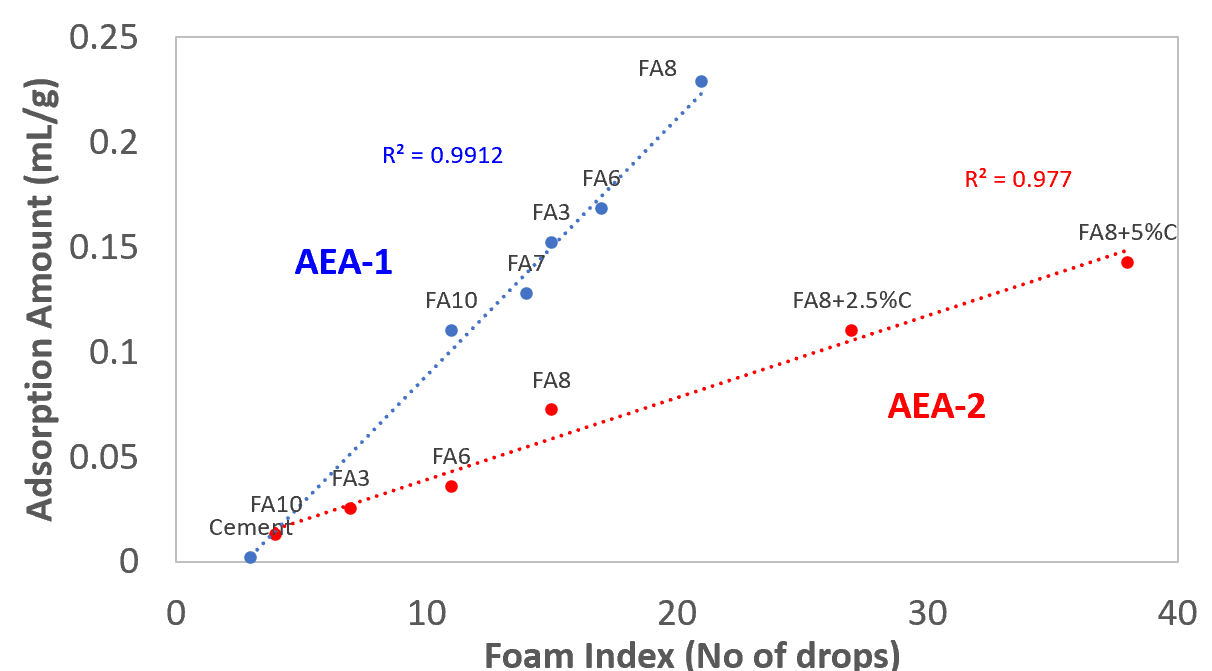

Fly Ash Adsorption Amounts vs Foam Index Drops

(Fly ash samples prepared in 100ml beakers for ASTM foam index experiments were filtered then analyzed by IDS)

Adsorption Kinetics of Flyash-1 with AEA-1

Adsorption Kinetics of Flyash-1 with AEA-1

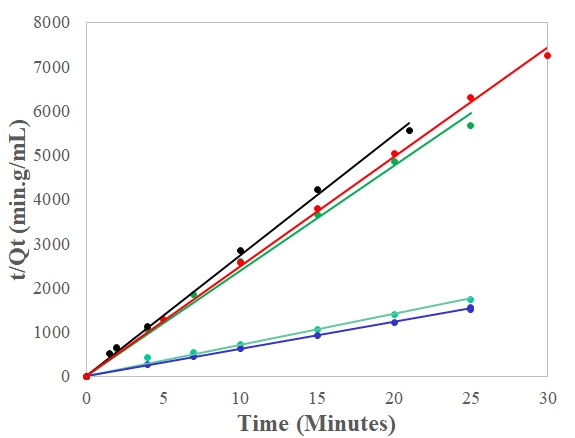

Pseudo-Second-Order Kinetics of Various Fly Ash & AEA Systems

Pseudo-Second-Order Kinetics of Various Fly Ash & AEA Systems

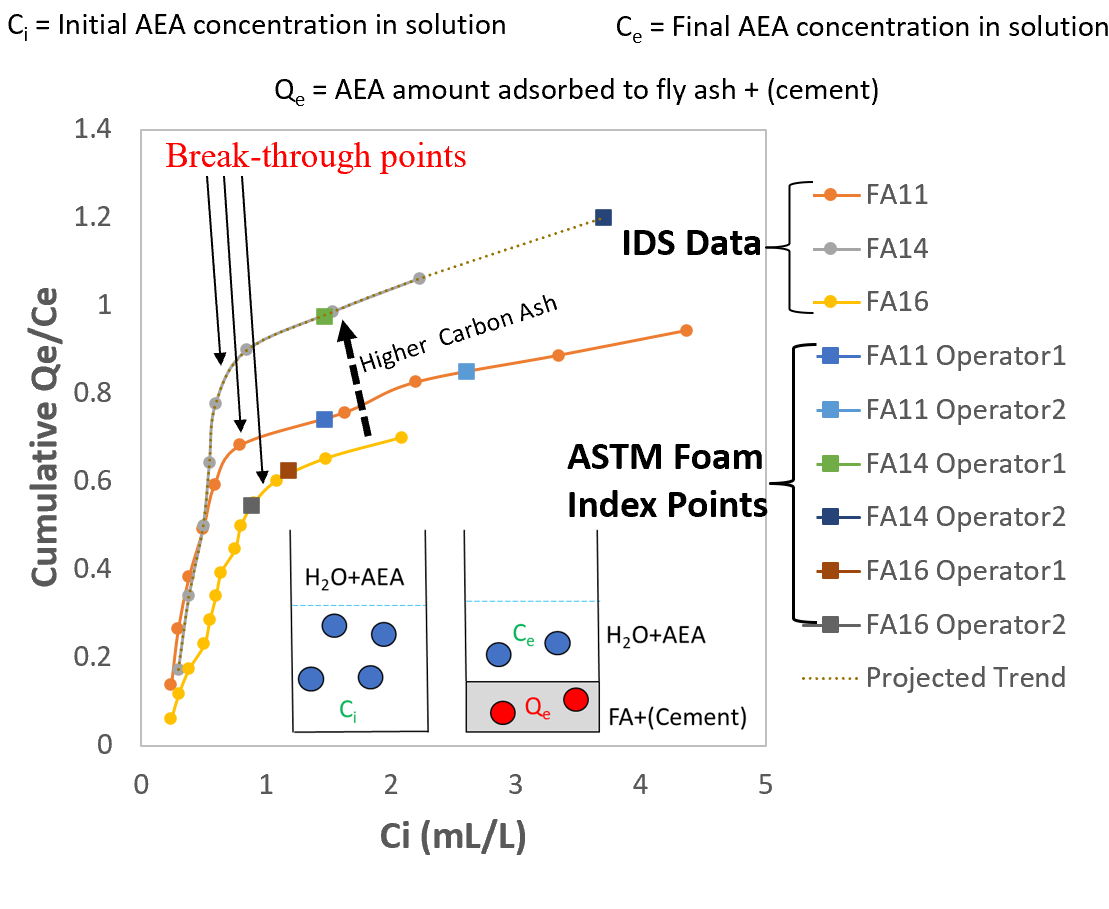

AEA Adsorption of Fly Ash with Different LOI

AEA Adsorption of Fly Ash with Different LOI

Notes & Observations:

- Foam index point (FIP) test results are subjective and vary between operators

- Adsorption capacity is affected by many variables. These include (A) fly ash variable such as particle size, fly ash treatment and surface area, and active carbon content; (B) Solution variables such as mixing temperature and time, mixing speed, initial AEA concentration present, AEA stability and shelf life; and (C) type of water (hard water/soft water) and ions presents or released into the solution by cement powders or aggregates.

- FIP variation gap between operators is larger for ash with high carbon content (Loss-on-ignition or LOI)

- Being a visual test, foam index equilibrium point does not always correspond to adsorption break-through point

- In multi-layer adsorption systems, adsorption increases at different rates with initial AEA concentration

- The IDS instrument can be effectively used to (1) compare the properties of different fly ash types used in concrete; (2) identify or develop optimal air-entraining agents (AEAs); and (3) determine the impact of the fly ash and cement mixing process on AEA adsorption and air bubble formation.